Project Background

The customer was the UK Ministry of Defence (MOD), specifically Air Command and other users operating rotary and fixed-wing aircraft (excluding fast jets). Aircrew roles ranged from pilots to loadmasters, working in diverse global environments and climates, including over-water operations. Any solution had to provide protection, comfort, and integration with the survival aids and equipment required to operate and survive in demanding conditions. Because the equipment attaches directly to the aircraft, the level of engineering scrutiny and compliance was equivalent to that required of aircraft components themselves.

Our Challenge

Aircrew needed a Body and Load Carriage System (BALCS) that was:

- Robust and comfortable for extended wear.

- Adaptable across different crew roles, from fixed pilot positions to mobile crew within the aircraft.

- Capable of carrying a wide and consistent range of equipment, including ballistic plates, weapon magazines, life preservers, radios, and extraction devices.

- Fully compliant with strict regulations, including EN ISO 13506 (fire retardancy) and AEP 2920 (ballistic protection).

- Designed and delivered by a DAOS-accredited organisation to meet airworthiness standards.

This was a highly regulated and complex requirement, demanding a significantly higher level of assurance than typical load carriage systems.

The Requirement

The MOD required a system that enabled aircrew to carry all necessary survival aids in any global operating environment with minimal physiological burden.

The capability had to ensure safety in two critical scenarios:

- Under fire: providing ballistic and fragmentation protection as the last line of defence.

- Emergency landings: enabling crew to evacuate aircraft, defend themselves, and survive in hostile environments with carried survival aids until rescue.

Our Solution

Level Peaks conducted a global market analysis in close collaboration with the customer, identifying and integrating the best available products into a single system.

The final BALCS brought together components from four different companies, all selected for maturity and reliability to ensure compliance with stringent MOD requirements.

Level Peaks recruited specialist engineers with MAA and DAOS experience to ensure that airworthiness and engineering standards were met. The system underwent formal testing, including EN ISO 13506 fire tests, before entering MOD trials.

The solution was designed to:

- Deliver high levels of ballistic and fragmentation protection.

- Integrate a life preserver with sufficient buoyancy for male and female aircrew (5th–95th percentile).

- Reduce overall weight while maintaining comfort and functionality.

- Accommodate approximately 20kg of essential equipment without compromising movement or safety.

How we Implemented it

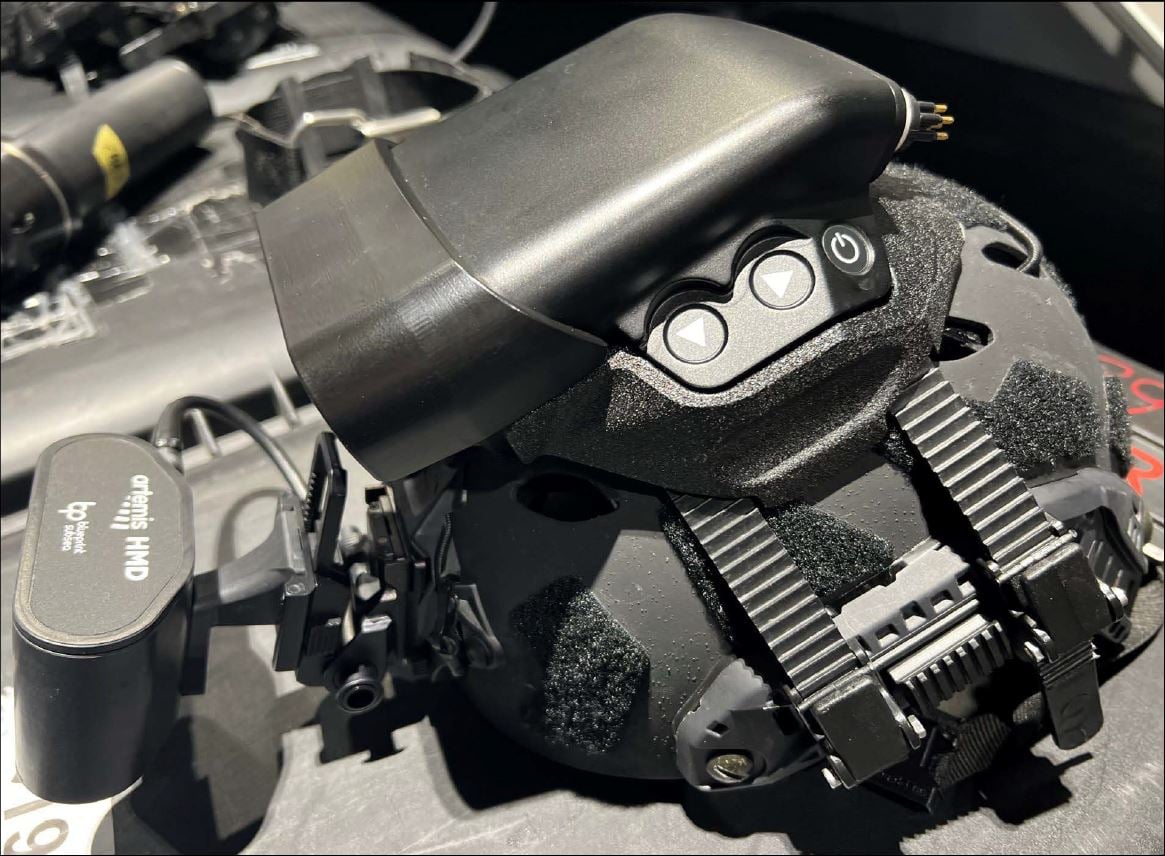

Following a competitive MOD tender, the Level Peaks system was selected as the preferred solution. The R&D and early testing ensured a smooth transition into manufacturing. Over the last 10 years, more than 2,500 systems have been delivered. The contract has been awarded back to Level Peaks on three occasions, validating both the design approach and the company’s DAOS-accredited processes. Collaboration was central to delivery, involving partners such as Eagle Industries, Aerial MT, Luminae, and Elbit Systems UK, alongside multiple independent test houses, including BTTG, FOSC, and Intertek.

Outcome

The system has been in service for over a decade, continually evolving to meet emerging requirements. Key outcomes include:

- More than 2,500 systems delivered across the UK MOD.

- A 25% weight reduction compared with the original system, improving comfort and mobility.

- Enhanced operational capability by ensuring aircrew remain protected, mobile, and equipped for survival in all environments.

- Proven reliability and performance under operational conditions, supporting mission success.

Our Ongoing Support

Level Peaks continues to provide engineering and technical support for design changes, repeat orders, and supplier assurance visits. They maintain a strong working relationship with both the MOD Procurement Authority (DE&S) and end-users, ensuring the system remains current with latest design, manufacturing, and technological developments.

Loan systems are provided during servicing to guarantee that units are never left without operational capability.